This page is intended to show details on the pool for those considering helping us in getting the equipment/liner so we can swim. The basic size (see the bottom of this page for detailed, within 1/8 inch, measurements) is 13 ft wide, 75 ft long and going from around 3.5 ft at the shallow end to 5 ft about 50 ft in, then going from 5 ft to 7 ft to the deep end. I calculate this produces a volume of a bit more than 4,600 cubic feet or around 34,500 gallons. The pool is inside a greenhouse where the air will always get to at least 80 F on sunny days even in the dead of winter and there is a heater for the greenhouse with a thermostat to keep the temp no less than 55 F. The pool structure is made out of pressure treated wood (see pictures below) based broadly on plans found on the Internet (Sunland Pools (http://sunlandpools.com/) though they don't appear to be offering such plans any longer). The 6x6 posts are spaced 8 ft or less apart and the bases are held by a steel 'bootie' that is embedded in concrete (which, in nearly every case, is embedded in bedrock). The walls are made of horizontal 2x12s 16 ft long (so they reach three posts) on 1 ft centers with vertical sections of 2x12 also on 1 ft centers. The interior and exterior walls are of 3/4 plywood. Approximately 2 ft or less of the pool is above ground, the rest is in the ground. Except for the rear of the pool where there is an equipment room, though the top of that wall is (will be) diagonally braced with 2 - 6x6 posts with the load transfered to the equipment wall footer. The pool has a gutter (trough) edge and we used a water level to set the height. The gutter drains to the deep end of the pool where it will then drain into a sump and from thence to the pump/filter/heater/sanitizer. The return water will travel along both long edges of the pool underneath the pool edge (which overhangs into the pool about 4 inches) inside PVC pipes with holes drilled into the pipe directing the water into the pool. Thus, there are no designed holes in the liner. The gutter will be lined with fiberglass and should be entirely waterproof.

We would like to get lane markings since we consider this a lap pool. We got this information from USA Swimming:

103.5 POOL AND BULKHEAD MARKINGS

.1

Pool bottom lane markers:

Minimum 10 inch (25 centimeter) wide lines of a dark contrasting color (preferably black [in our case, probably white is better since we expect to use a dark liner]) shall be provided in the middle of each racing lane on the bottom of the pool. The lines should be uninterrupted the length of the course and shall end with a distinctive cross line 1.0 meters (3 feet 4 inches) long and the same width as the bottom marker. The line, including the cross line, shall terminate 2.00 meters (6 feet 7 inches) from each end wall.

.2

End wall targets:

Flush, non - slip targets in a shape of a T or a cross and the same width as the lane bottom markers shall be provided in the center of each lane on each end wall of the course and shall extend at least 3 feet 4 inches (1.0 meters) below the level of the water surface. It is recommended that the top edge of the deck be of a contrasting color to provide a visual target above water at the end of the course.

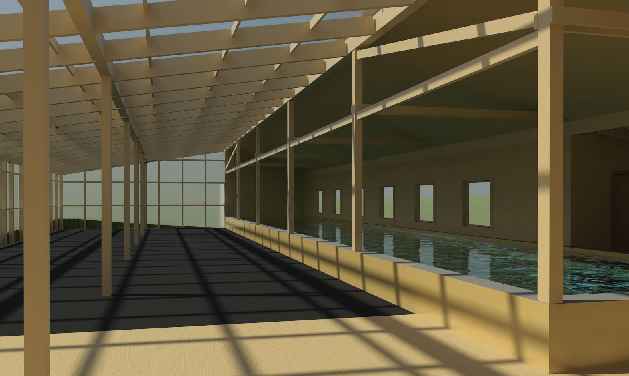

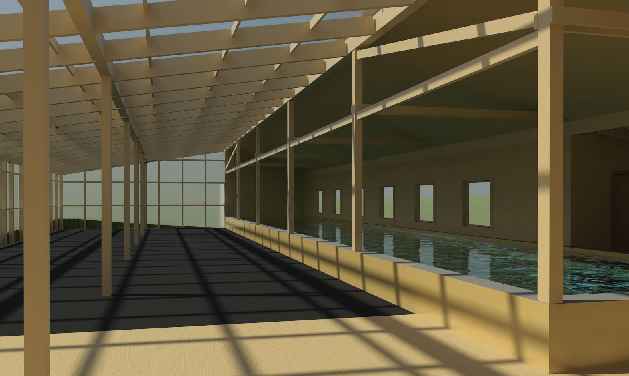

Engineer's rendering of the plans:

Here are the PDF plans the engineer drew up for the permit.

Below are a selection of links into our 'blog' detailing our construction efforts. These pages have been selected because they show the steps in construction, but serve only as a reference.

These are detailed pictures of the nearly complete pool. What is lacking is the extruded polystyrene on the floor to protect the liner and the fiberglass coating on the gutter.

These pictures show the walls of the pool and ends from different directions...

This is from the shallow end looking toward the driveway side:

This is from the shallow end looking toward the greenhouse side:

This is looking from the middle toward the shallow end:

This is looking from the middle toward the deep end:

These two pictures show the corner of the pool. We placed a 'wedge' in the corner since the tight 90 angle seems to be problematic based on feedback we have had. This is not secured, so if there is a less expensive way to manage the corners we are happy to consider other options. We would like to have the liner corners fabricated so they can fit over the corners. The straight sides shouldn't be any issue at all.

To give an idea of the size of the 'wedge', here are a couple of pictures with a measuring tape:

These two show how the liner would be installed with the 1" schedule 40 PVC pipe channel. The two above picture as installed, the next two give some additional views. Between the liner and the walls of the pool will be the sheet of protective foam and at the bottom of the pool will be 2 inches of extruded polystyrene.

These last four show the 2" extruded polystyrene we are using to protect the liner from the gravel at the bottom (the measurements below reflect the presence of the polystyrene). Along the edges of the bottom of the pool we have also placed 'wedges' as a way to make the corners easier to fabricate (or at least we think so). If there are cheaper ways to manage the corners we are happy to consider other options.

Here is a view showing the polystyrene 'wedge' at the bootom of the pool along with a measuring tape for reference:

We did a detailed measurement of the pool dimensions and came up with the following:

| shallow end | deep end |

| width | 13' 2.75" | 13' 2.25" |

| left (greenhouse) side | right (driveway) side |

| length | 74' 11.5" | 74' 10.25" |

We measured one of the diagonals (from the driveway side at the shallow end to the greenhouse side at the deep end) at exactly 76 feet.

This is a table with the measurements of the pool. These measurements are from the top of the polystyrene that will link the bottom of the floor to the top of the plywood representing the gutter edge. NOTE: we expect the height of the liner to exceed these measurements by 4+ inches as we need to wrap it into the gutter and will trim off the rest later.

| distance from shallow end (feet) | depth left (greenhouse), inches | depth right (driveway), inches |

| 0 | 41 1/2 | 41 3/4 |

| 3 | 42 3/4 | 42 1/4 |

| 7 | 44 1/4 | 44 1/4 |

| 11 | 45 1/2 | 44 7/8 |

| 15 | 46 1/4 | 46 |

| 19 | 46 7/8 | 46 1/4 |

| 23 | 47 1/4 | 46 5/8 |

| 27 | 47 7/8 | 47 3/8 |

| 31 | 48 1/4 | 48 1/4 |

| 35 | 49 1/4 | 49 1/4 |

| 39 | 50 1/8 | 50 1/2 |

| 43 | 51 1/4 | 51 1/2 |

| 47 | 52 7/8 | 53 1/4 |

| 49 | 55 | 54 3/8 |

| 51 | 57 | 55 3/4 |

| 53 | 59 1/2 | 57 3/8 |

| 55 | 62 1/8 | 60 1/8 |

| 57 | 65 | 62 7/8 |

| 59 | 67 7/8 | 66 |

| 63 | 73 1/2 | 72 |

| 67 | 78 1/8 | 77 1/8 |

| 71 | 82 1/8 | 81 3/8 |

| 75 | 85 7/8 | 84 3/4 |

Here is a graphical view of the pool bottom profile (note it is 'upside down'):

The two sides of the pool don't exactly match and if it is a signficant (read expensive) issue we can level the pool again side-to-side to within a half inch.

If you have any questions, please email me at mitakeet [at] gmail [dot] com.